Filtration & Environment

Condensat Separator

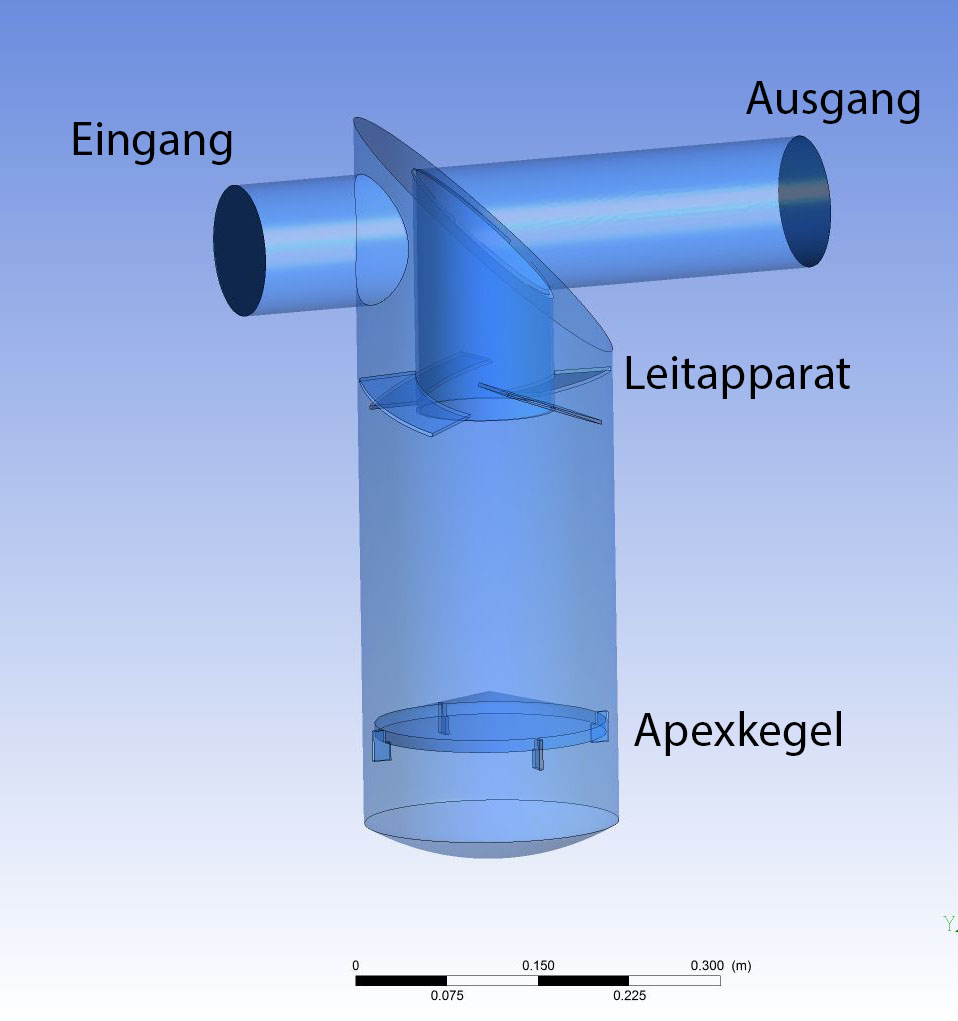

The ABZ droplet separators are optimized spin centrifugal separators for the separation of liquid drops from gaseous media, such as air or process gases. The droplet separators are typically used in processes with phase transition (liquefaction). This is usually the case with vacuum pumps, refrigerators, heat exchangers, as well as with steam and heat technology where condensates are produced. Since the working processes of these machines are often carried out under pressure, the type ABZ drop separators are built as an axial cyclone. This means that the twist movement is generated by means of a guide device inside the separator, which avoids the spiral, tangential entry: the droplet separator can now be built symmetrically, which makes a pressure-resistant design easier to implement. The droplet separators are designed according to the calculation instructions AD2000 Merkblätter.

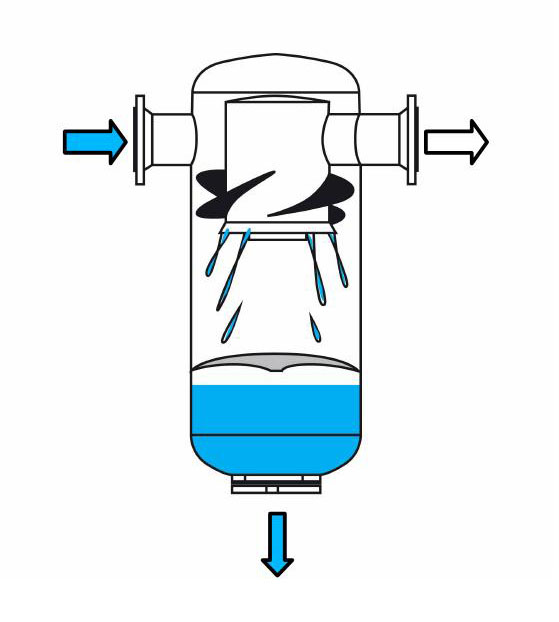

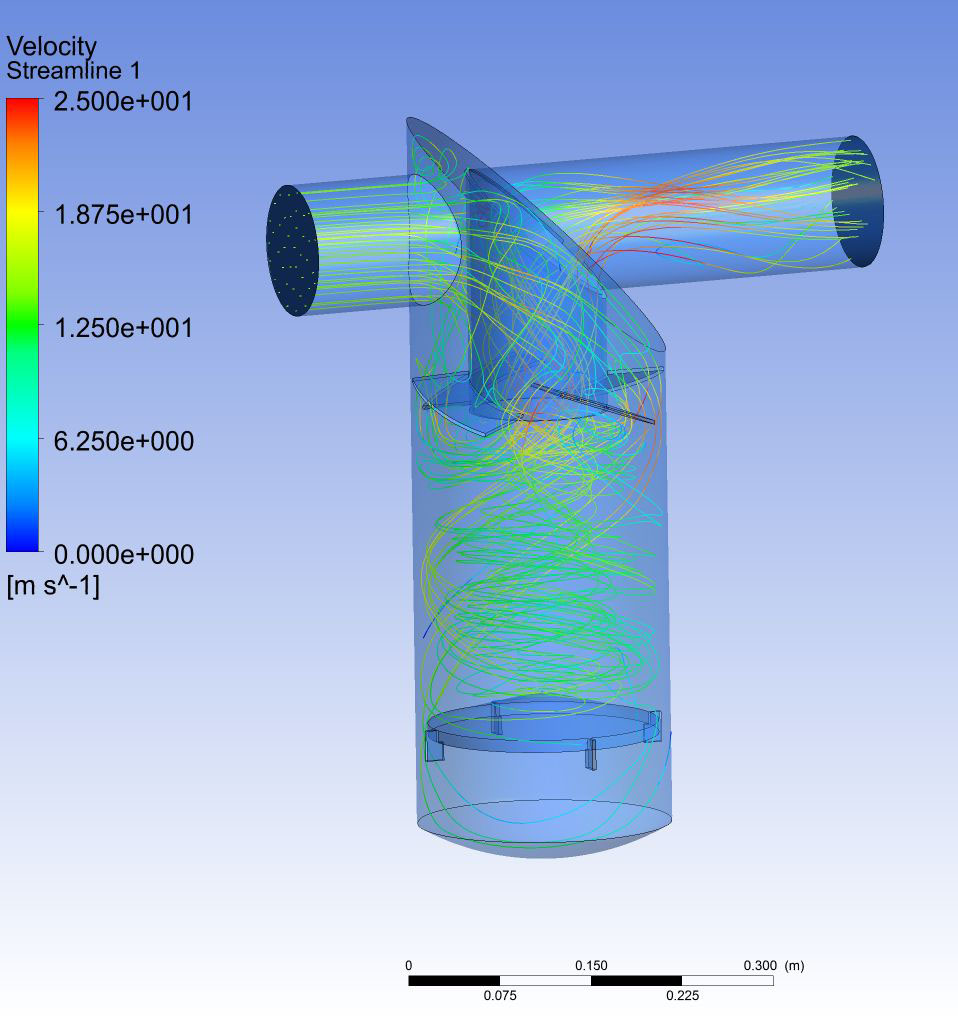

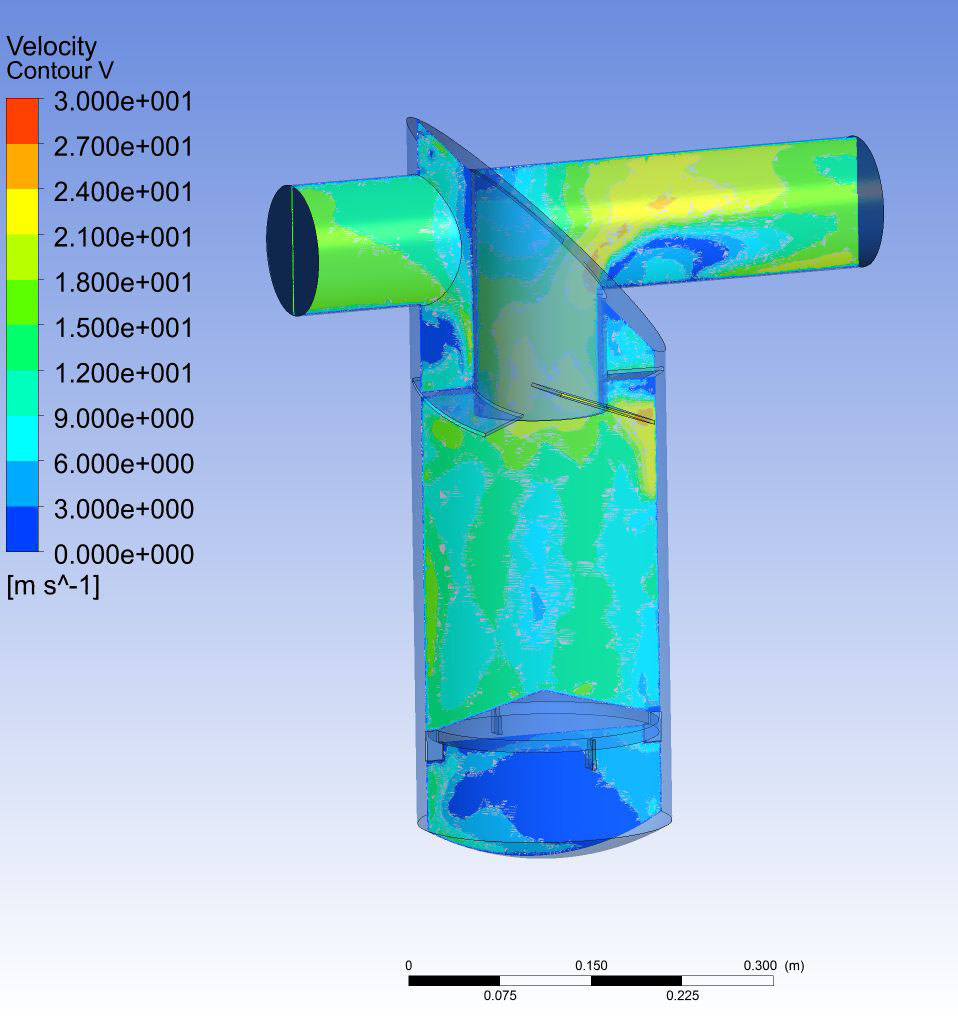

Function

In the case of the droplet separator type ABZ, the gas flows radially into the upper part of the separator and is deflected in the axial direction. During subsequent flow through a guide apparatus, a swirl flow is generated by means of guide vanes. The gas and the droplet particles contained therein move on spiral-shaped orbits. As a result of the curvature of the webs, strong centrifugal forces are produced. The curved vanes further prevent entrance losses and flow detachments. The centrifugal forces carry the droplet particles radially to the outer wall. The particles slide into the collection space and are thus deposited. The purified gas leaves the separator through a central dip tube. A shielding of the collecting space prevents the entrained condensate or the separated solids from being entangled and entrained.

Selection criteria

• Droplet size distribution in front of the aerosol separator / condensate separator

• Droplet loading of the flowing gaseous media such as air or process gases

• required separation efficiency

• Permissible pressure loss

• Solid loading of the drops

Separation:

• of condensates:

99,5 % for droplets of the sizes 8 – 10 um

• of particles:

99,9 % for particles up 5 um

Pressure drop:

Since the pressure losses depend strongly on the gas properties, as well as on the thermodynamic characteristics of the process, the pressure loss is calculated individually for each application.

Versions:

Material: C steel, stainless steel 1.4301, 1.4541 or 1.4571, matt stained.

Construction according to AD 2000 regulations or other regulations.

Acceptance: TÜV

Flanges according to DIN 2633 or DIN 2632