Filtration & Environment

The Continuum technology compact dust collectors are suitable for numerous applications and types of industrial dust. They extract dry suspended dust directly at the point of origin and thus create the prerequisite for a clean production environment. The mini dust collectors are used to suck clean individual workstations and dust-creating machines of all kinds. The collectors are fitted with filter cartridges or filter pockets, which can be cleaned manually or automatically Pulse Jet during operation. The compact dust collectors can also be used in the case of hazardous substances in combination with an H13 secondary filter. The filter housing has a high-grade powder coating both inside and outside.

Upon entering the filter housing, the raw gas flows against a deflector, thus achieving a separation of coarse particles already before it reaches the filter cartridge (sifter effect). In this way the filter cartridge is also shielded against abrasive particles. The coarse dust thus falls straight into the drawer. The raw gas subsequently flows through the filter cartridge, thereby achieving clean gas values of less than 2 mg/m³. Applying an electronically controlled filter cleaning process, the dust is cleaned from the outside of the filter cartridge by means of air blasts during operation. The cleaning system is equipped with a venturi nozzle and displacer. The venturi nozzle causes an intensification of the air blasts, while the displacer in turn reduces the dead volume inside the filter cartridge. The result is a high degree of cleaning with minimum compressed air consumption. The cleaning may take place by time or, optionally, by the pressure difference via the filter cartridge.

Dedusting:

The inflowing dust-laden air is pre-cleaned by a deflector plate to protect the filter elements, the remaining particles are detached on the surface of the filter cartridges. The dust adhering to the filter medium is separated by means of pulse-jet cleaning. The vertical arrangement of the filter cartridges, together with the venturi nozzles above them and displacers inside the filter cartridges, permit efficient cleaning. As a result of the fully automated filter cleaning a constant extraction performance is achieved. The detached dust falls into a rollable dust collection container.

AirControl

Max. filter surfaces: 16 m²

Max. airflow: 1800 m³/h

Dimensions: > (L) 700 x (W) 700 x (H) 1750 mm

Number of cartridges: 1 - 4

Product Description:

The AirControl cartridge filter can be employed universally for the suction cleaning of individual workstations or machines. It is used to filter dry dust, shavings, granulate, flour and powder. With the aid of an optional secondary filter it is also possible to extract particularly subborn smoke, dust, etc.

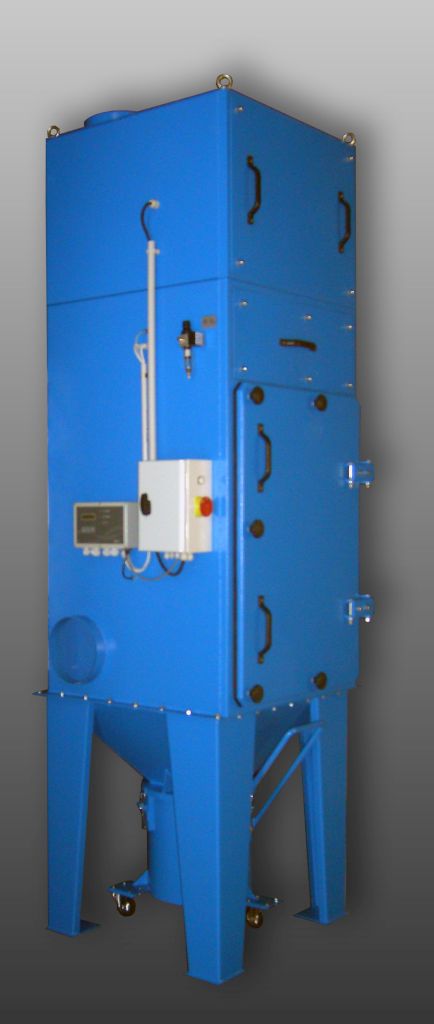

AirTower

Max. filter surfaces: 36 m²

Max. airflow: 2200 m³/h

Dimensions: > (L) 830 x (W) 830

Number of cartridges: 2 or 4

Product Description:

The AirTower cartridge filter can be employed universally for the suction cleaning of individual workstations or machines.

VarioJet P

With fitted fan

Max. filter surfaces: 72 m²

Max. airflow: 4300 m³/h

Dim. > (L) 1080 x (W) 1080

Number of cartridges: 4 or 9

With external fan

Max. filter surfaces: 189 m²

Max. airflow: 11000 m³/h

Dim. > (L) 1050 x (W) 1600

Number of cartridges: 6 or 9

Dedusting

Process technologies:

• Surface treatment - brushing, polishing, grinding, sanding belt

• drilling, sawing, turning, milling, cutting

• painting, powder painting, sandblast

• crushing, grinding, dispersing

• screening, separating, sorting

• Mix, dry

• Pack

• Recycling

Products

• Metal

• Plastic

• Paper

• Rubber

• Leather

Benefits

• Standard filter cartridge

• Optimal cartridge cleaning

• Longer cartridge life

• Easy maintenance