Powder Engineering

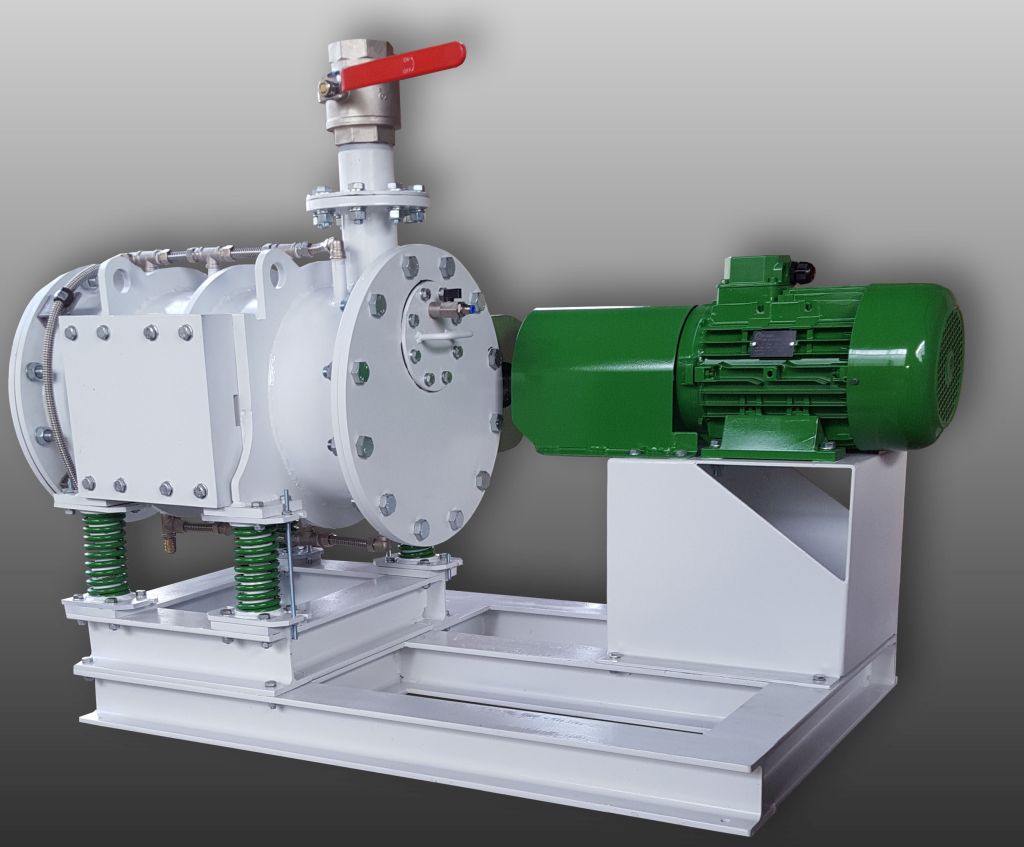

The eccentric vibrating mill CVM is a monotube mill, which consists of several modules. Figure 1 shows schematically a module. Is the excitation unit consisting of bearing body and unbalanced mass, which is connected through a propeller shaft to the drive on one side of resiliently suspended grinding tube. For mass balance with respect to the excitation unit a balancing mass is located.

The construction of the eccentric vibrating mill CVM, the energy input was increased so that the proportion of low-energy zones could be largely minimized and the date-related upper limit of the diameter of the grinding tube could be increased more than 650 mm beyond.

Compared to conventional tube vibration mills, which have a central drive, the eccentric vibrating mill CVM elliptical, circular and linear vibrations executes the same time, lead to far not reached oscillation amplitudes and associated high degree of loosening the grinding media.

Special Features:

• Increased performance by a factor of 2 compared to your traditional vibratory mills

• Reduction of energy consumption up to 50%

• Increase the feed size to 20 mm, thus skipping a stage of crushing

• development of new applications, for which there was no suitable grinding machines

• Adaptable to any Mahlprobleme modular design

• ease of use and ease of maintenance by coupling the unbalance drive on Mahlrohrmantel

• Reduction of production costs by avoiding central drive units

Versions:

The mills are according to customer gefertigt.In rule is this:

• lining of the mill with elastomers, ceramics and highly wear-resistant hardfacing

• grinding of steel, carbide and ceramics of various Qualitätn

• Additional cooling or heating of the grinding container

• grindings in vacuum and in an inert gas atmosphere

• Special solutions for the filling and emptying

• Total assets including peripheral systems

Function

The eccentric vibrating mill has a cylindrical grinding container with grinding media. On a grinding tube exciter module is mounted outside of the center of mass. The drive unit is mounted parallel to the axis opposite the balancing mass. The grinding pipe is resiliently mounted on a frame construction on coil springs. The filling of the mill with grinding material via a pipe connection at the top of the grinding tube and the discharge of the ground material over outlet spigot at the lowest point on the opposite end of the grinding tube. The outlet pipe is provided with a perforated plate, so that the grinding media are retained.

The drive of the mill via a propeller shaft by a three-phase motor. The inhomogeneous vibrations are generated by means of excitation module in the form of a bearing block with imbalances. The advantage of the one-sided excitation is that the usual circle vibration is complemented by inhomogeneous oscillations as ellipses and linear oscillations. The extent of the linear vibration causes an increase in the velocity of the mill filling compared to circular motion vibrating mills by approximately a factor of 4, so that in addition to increasing the normal impact force, especially an increase in the frictional shall be measured.

It is characteristic of the unilateral excitation outside the gravity axis and the center of mass of the vibrating mill that, in contrast to the usual circular motion vibrating mills the rotation of the mill filling takes place only if the pathogen is up to the grinding tube dreht..Der advantage of unilateral excitation of the eccentric vibrating mill that the additional occurrence of elliptical and linear vibrations contributes essentially to improve the transport processes by increasing the rotational speed, which is crucial for the grinding progress.

Eccentric vibrating mill is modular. Each module consists of milling tube and the excitation module. The Mahlrohre can be connected to the flange. The individual excitation modules are synchronized by means of drive shafts. In this way, the length of the mill is adjusted according to the Mahlaufgabe. Up to 4 modules can be connected.

Applications

The mill finds its application in the manufacture of powders, pigments and dusts in the chemical and ceramic industry and processing of raw materials. In the stress of materials on impact, the Hauptbeanspruchungsart of vibratory mills, in addition to the increase in surface area and crystal lattice defects can be achieved so that influence can be exerted on the material properties.

The eccentric vibrating mills are suitable for wet and dry grinding of brittle materials of all degrees of hardness. The maximum feed grain size can be up to about 15 mm. The feed material may vary depending on its material properties and the grinding down to 0 - 5 to be crushed. The great advantage of vibratory lies in the fine grinding of dry goods and in the possibility of mechanochemical activation of raw materials and residues.

General applications are:

• intermittent dry and wet fine grinding

• mechanochemical activation of raw materials and residues

• dry homogenization of powders and dopants

• chemical-physical process management (reactor)