Powder Engineering

Since the single-stage grinding for the production of very fine particles is often insufficient, impact mills are also equipped with a classifier wheel. The Classifier CCM thus combines a mechanical impact mill with a dynamic classifier. It offers the possibility in a system with comparatively little effort to produce particles with very fine size distributions. The integration of mill and classifier in a single package provides the following benefits:

• Easy to clean

• Simple construction

• compact grinding plant

Applications

The Continuum Classifier, Type CCM is a very flexible machine for the production of fine powders with a defined upper particle size limit. The Classifier CCM is softer used for dry fine and ultra-fine to medium-hard materials up to a Mohs hardness of 3.5. The de-agglomeration of products is possible even for products with a Mohs hardness of 5. It can be reached particle sizes between 10 .mu.m to 200 .mu.m. The integrated classifier there is a precise definition of the upper grain boundary. High flow rates allow processing of temperature-sensitive products.

Special Features

• Suitable for milling drying

• Low temperature increase also in constant operation

• Rinsing Lagererung and classifier

• Easy to clean for quick product changeover

• optimized diffuser: recirculation optimized for high grinding capacity

• interchangeable diffuser suitable for various products to increase efficiency

• sensors to monitor the bearing temperature and vibration

Versions:

• Pressure resistant up to 10 bar g

• classifier wheel - different heights and different number of Sichterblätter (diagonally, radially arranged)

• grinding disc - different sizes and materials, different number of Mahlhammer

• Depending on the application, different materials: treated (stainless steel, special steel, ceramics), surfaces or polished, wear protection.

• various grinding elements (grinding pins, smooth or notched Mahlblöcke)

• Various Mahlbahnprofile

Function

The ground material passes pneumatically via the tangential inlet to the mill. Due to the turbulent flow in the grinding zone, the ground material is distributed evenly over the grinding disc. The material is ejected by the impact on the rotating grinding tools against the stationary grinding path. In this case, it is crushed successively. After the impact on the grinding track, the ground material is passed through the flow into the classifier zone. In the classifier zone, the ground material is supplied by means of a guide vane on the classifier wheel. Which grain size is transmitted through the dynamic classifier, can be determined by the amount of air and the classifier and modified during operation. The coarse particles are returned to the painting process. The fine particles that pass through the classifier wheel are exhausted and collected.

Benefits

• Sharp, easily adjustable cut-off (during operation)

• Low temperature rise of the product

• exact upper particle size limit can be set during operation

• steep particle size distribution

• robust and proven design

• High throughput

• low Lärmemisionen

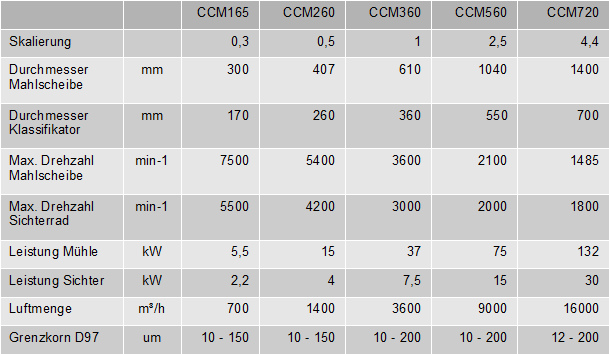

Model